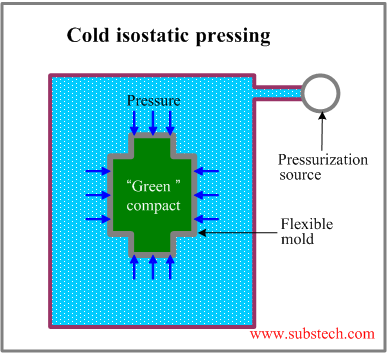

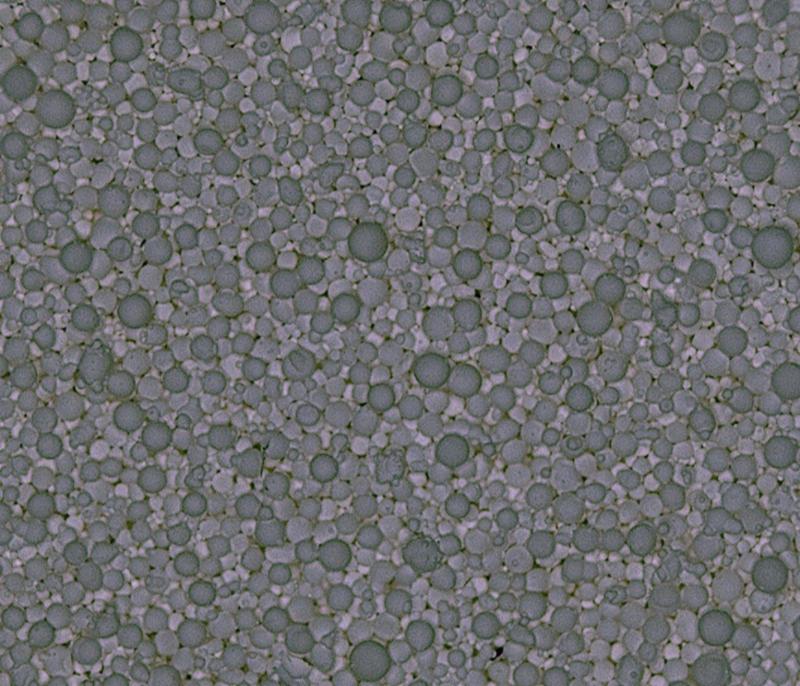

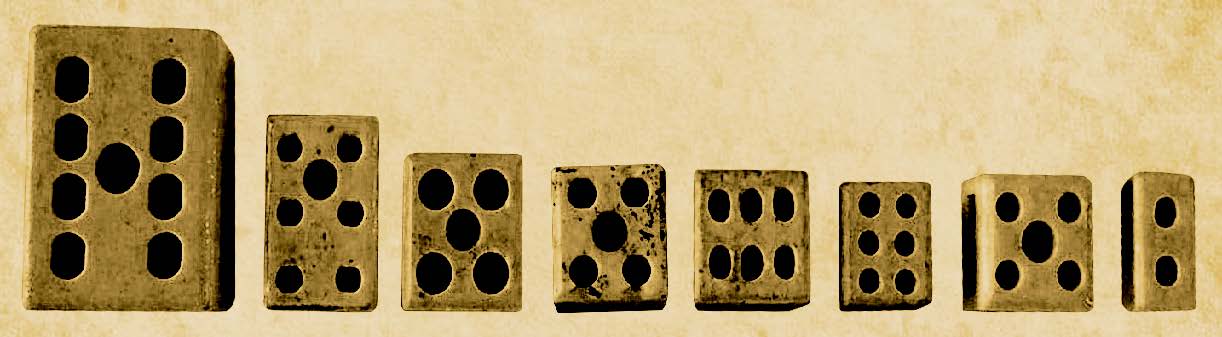

Compaction of ceramic powders is a forming technique for ceramics in which granular ceramic materials are made cohesive through mechanical densification either by hot or cold pressing.

Ceramic compaction presses.

The compaction process permits an efficient production of parts to close tolerances with low drying shrinkage.

The range of compaction force of mechanical presses for products of the technical ceramics is 2500 kn what is caused from the less density of the ceramic materials.

Powder compacting is a compression molding process that uses a press usually hydraulic to form complex shapes from metallic ceramic composite ptfe and other powder compounds.

To arrange an inspection or your purchase dial 1 810 225 9494.

A full range of powder compaction and sizing solutions for a full range of applications.

Gasbarre pess is iso 9001 2015 certified.

Normally the upper punch lower punch and die systems of mechanical presses don t work on base of multi subdivided punches.

Exclusive offer by mohr corporation.

Hydraulic presses custom designed to your specific compaction pressure and fill depth requirements these presses feature robust 4 column or monolithic frame construction and can be designed for the buyer s exact application requirements to accommodate any specific compaction pressure and fill depth required for optimal production.

Gasbarre has decades of press building experience offering standard and custom equipment solutions.

Beckwood typically uses a multi action design for powder compacting presses because it allows operators to set fill heights via the lower or middle action while also.