Upon curing xp 61 becomes a durable ceramic coating that will provide protection to boiler and furnace tubing and other steel substrates to 871 c and will withstand thermal cyclic conditions to 982 c.

Ceramic coating for boiler tubes.

They are specially formulated to protect process equipment exposed to aggressive high temperature environments like industrial boilers kilns and fired heaters in petrochemical refineries.

Green eco i optēcoat coatings for protection of boilers in power plants.

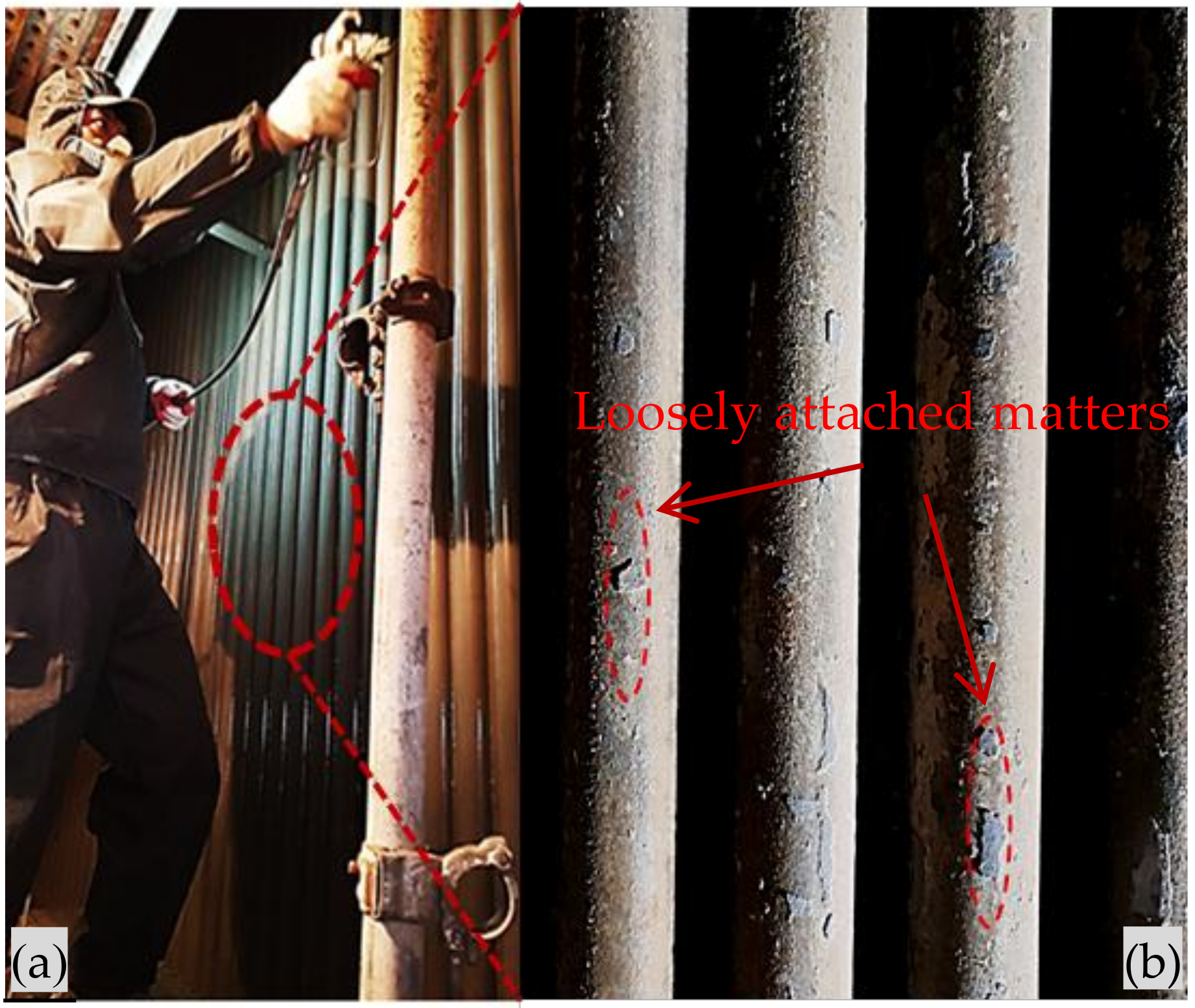

Hard dense boiler tube coatings to mitigate wear and corrosion.

High velocity thermal spray metal coatings to prevent acid corrosion of boiler s waterwalls and superheaters.

Slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising.

Greenshield ceramic boiler tube coating is designed to protect solid fuel fired boilers from corrosion slagging and erosion.

Repair coatings inside cfd boilers.

Efficiency is accomplished by increasing thermal transfer of the process tubing while also retarding tenacious slagging and scaling.

Hvaf hvof equipment and services to protect and repair boiler tube coatings on site.

1 866 591 9018 email protected.

Fmp s ceramic coatings for coal fired boiler tube outperforms the competition.

1 905 676 1969 f.

Cr3c2 nicr coatings to mitigate wear and sulfur corrosion of waste incinerators.

7065 tranmere dr suite 6 mississauga on l5s 1m2 canada t.

Improves heat transfer and enhances thermal management for lower furnace exit gas temperatures fegt.

Ceramic coatings on boiler tubes using fireside coating llc ceramics protection against erosion erosion and corrosion at high temperatures.

Furnace mineral products inc.