Whenever you put time or expensive lumber into a clear finished project it doesn t make sense to use anything but stainless steel.

Ceramic coated scres vs stainless steel.

Stainless steel ensures the better strength of the screws.

Star drive allows easy and fast installation.

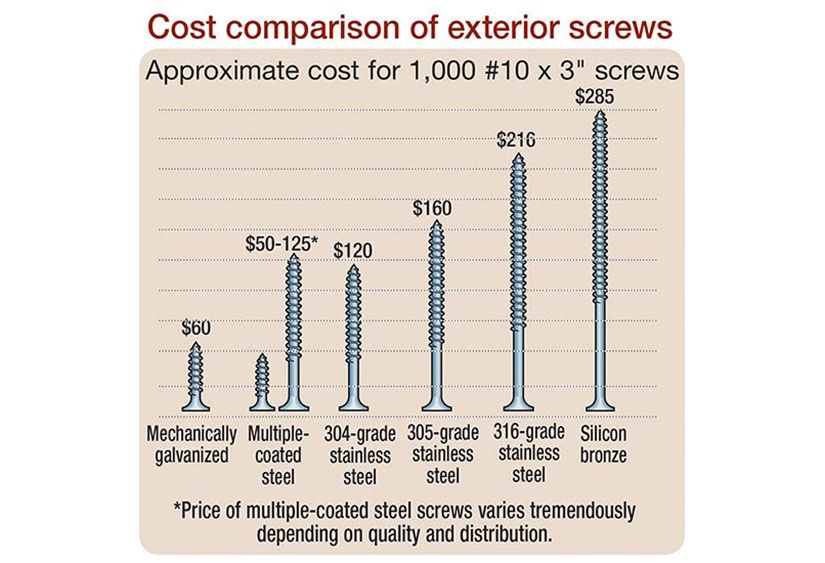

Any manufacturer s stainless steel products will cost more than its coated steel ones.

100 qty 8 x 1 5 8 features.

However stainless steel is reactive with aluminum and when a stainless steel screw is in contact with an aluminum base metal the aluminum is likely to corrode.

The presence of this tough metallic element improves the durability of the steel and adds rust resistant qualities as well.

For instance titan metal werks a fastener manufacturer charges about 25 for 400 of their acq rated zinc coated with a polymer topcoat 6 by 2 inch splitstop screws.

As is the case with carbon steel screws a plated stainless steel screw is less likely to corrode aluminum.

But these fasteners are expensive.

But stainless steel is well worth it if you don t want to see any rust or stain marks on your project.

Composite deck screws can also be stainless steel but are available in colors designed to compliment and match the colored deck boards trim and railing components.

In any case ceramic is never going to hurt power.

Building supply dealers and catalogs may offer as many as five different types of stainless steel screws.

So if you need stainless steel deck screws these are one of the best options for you.

For corrosion resistance stainless steel is the best of the lot.

Ceramic coated screws can be used with both pressure treated lumber and composite decking.

Please make your contractors aware prior to purchasing ceramic coated screws of the following.

A more widely seen option is epoxy coated deck screws.

Ultra guard tan coating ensures corrosion resistant property.

It is an alloy that includes a significant quantity of chromium.

Basic stainless steel sold as type 302 303 304 or 305 contains 18 chromium and 8 nickel plus other alloys.

Headers coated inside and out with ceramic should last just this side of forever or at least comparable to stainless.

In contrast stainless steel does not need to rely on a coating to toughen and protect it.

Screws treated with a high quality coating consisting of zinc and aluminum.

Corrosion resistance and ceramic coated screws posted on jul 07 in news.

In terms of durability and corrosion resistance stainless wins over mild steel headers that are coated only externally with ceramic.

Ceramic coated screws have performed extremely well in salt spray testing but this does not mean they should be substituted for stainless steel in a marine environment.